class a foam acts as a surfactant which means that it

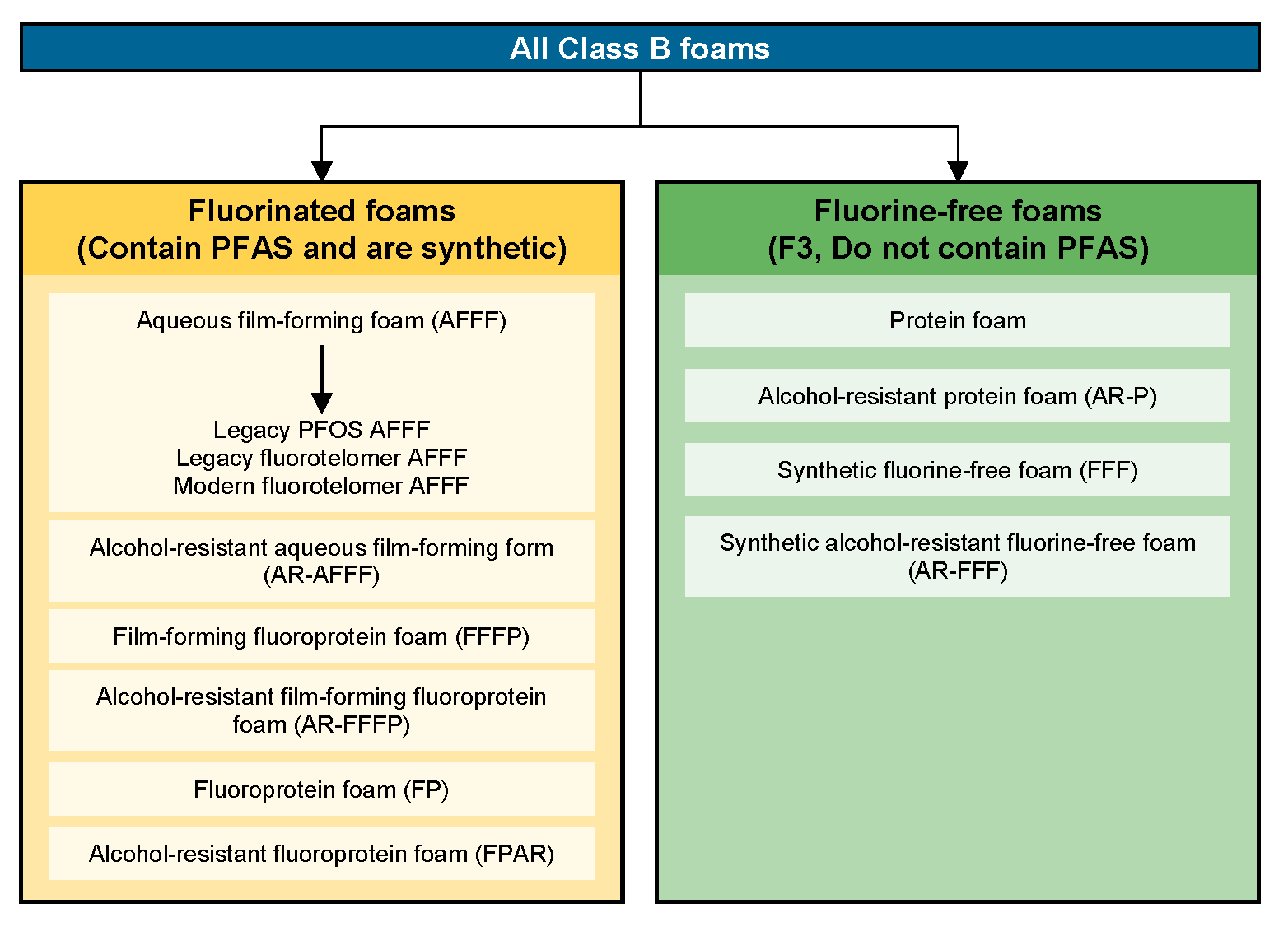

Aqueous film forming foam AFFF means a fluorinated surfactant with a foam stabilizer which is diluted with water to act as a temporary barrier to exclude air from mixing with the fuel vapor by developing an aqueous film on the fuel surface of some hydrocarbons which is capable of suppressing the generation of fuel vapors. The fluorinated surfactants used in AFFF are produced by one of two synthetic processes 1.

Ingredient Spotlight Surfactants

The second reason that surfactants help create foam is that the liquid in the foam walls is naturally sucked out of the walls into the edges.

. When added to water the resulting foam solution consists of many smaller droplets with much more surface area allowing faster heat absorption. The energy need to increase the surface area A is γδAδt so a low γ means more foam for less energy. It reduces the surface tension of the water and.

When mixed with water in the correct proportion it changes the properties of water. Class A foam is for use against Class A fires such as paper rubber textiles and wood. National Foams Class A Foams are also wetting agents.

CAFS units may cost up to 40000 per vehicle. The negative charge helps the surfactant molecules lift and suspend soils in micelles. Class A foam is deployed through a variety of portable and fixed appliance.

Anionic surfactants have a negative charge on their hydrophilic end. Class A foam will increase wetting effectiveness. Tcholakova et al Role of surfactant type and concentration for the mean drop size during emulsification in.

Expand the foam solution at the nozzle by a factor of 4 41. Denkov et al Role of surfactant type and bubble surface mobility in foam rheology Soft Matter 5 2009 3389 review. The foam blanket consists of a mass of bubbles which places a physical barrier on the exposed surface and acts as an insulating blanket.

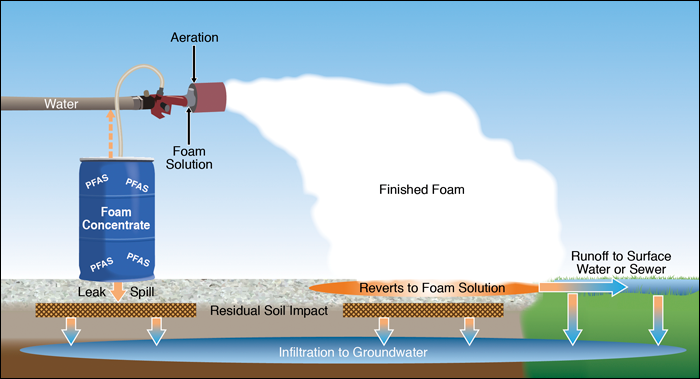

These are prepared by direct electrochemical fluorination. When Class B foams are sprayed with water the foam rises to the surface to create a vapor barrier to cut off the fuel source. As a fire barrier Class A foams increase moisture con-tent in Class A combustibles preventing the ignition of these type fuels.

Class B fires are best extinguished by smothering or applying a blanket of Class B foam which is meant to float on the surface of burning fluid. Water Foam Class A concentrate is simply a surfactant similar to dishwashing soap that reduces surface tension. This is nothing to do with drainage as explained in Drainage the walls contain an irrelevant.

Class B foam is used on flammable liquids. Class A foams are often intended for use at very low concentration of 01 to 1 and are formulated using environmentally favourable raw materials. Other components of fire-retardant.

Aerating nozzles and attachments greatly extend your foam supply by covering more of the. By adding the TFT nozzle attachment for foam operations the expansion ratio is 8 to 1. Class A foam surfactants stabilize liquid films foam bubbles in three ways.

Class A foams may be used as a firefighting agent or as a fire barrier. Environmentally responsible KnockDown a Class A foam concentrate is a unique formulation providing unmatched firefighting performance and flexibility. In addition the portion of the foam concentrate molecule that repels other water in order.

Class A foam is primarily a surfactant which is to say that it breaks down the surface tension of water. Water has a high surface tension and tends to bead up and cause run off. Class A foam is biodegradable and non-toxic so it is environmentally sustainable.

When mixed in correct proportions with water it can change two properties of the water. Anionic surfactants create a lot of foam when mixed. Class A foam is used on common combustibles such as paper wood and textiles.

One class of fluorosurfactants used in AFFF formulations is based on perfluorooctyl sulfonate PFOS and structurally related compounds. CLASS A FOAM CONCENTRATE. Class A foams are blend of surfactants that enable strong wetting and foaming properties.

Costs of equipment Departments reported equipment costs up to 5000 per unit for nozzle-aspirated class A foam systems. Costs for training Most departments did not quantify the cost of training their personnel to operate class A foam systems. As foam generation and also foam stability is a dynamic for process for generating and reducing surface area in a surfactantwater system the diffusion of the surfactant to the surface and the change in surface coverage at least locally during bubble generation and drainage of the film is a more useful way of explaining foam properties.

So a surfactant which reaches the lowest surface tension for the least amount of surfactant is in general going to give an easier longer-lasting foam. Difference was noted with nozzle-aspirated class A foam. When mixed in correct proportions with water it can change two properties of the water.

During the overhaulmop-up process. The surfactants used must produce foam in concentration of less than 1. These proportioning rates make the use of Class A foam a cost effective means of combating fires because relatively small amounts of foam concentrate can be used to make effective foam.

Qualified to USDA Forest Service 5011-307a and UL approved for use as a wetting agent for Class AB applications. This is a biodegradable mixture of foaming and wetting agents. Class A Foam Wildland Foam Class AB Foam Pyrocool Aqueous Film Forming AFFF Class A Foam Wildland Foam The foam is a non-corrosive non-toxic biodegradable concentrate.

Class B foams require special clean-up after a. When used as a wetting agent the concentrate lowers the surface tension of the water allowing better penetration into deep seated fires. Firefighting foam is a foam used for fire suppressionIts role is to cool the fire and to coat the fuel preventing its contact with oxygen resulting in suppression of the combustionFire-fighting foam was invented by the Russian engineer and chemist Aleksandr Loran in 1902.

Water draining from the foam blanket soaks into exposed Class A fuel and retards further combustion. The pressure inside a foam of radius R that contributes to its self-destruction is 2γR. Give the bubble film a viscosity that minimizes drainage.

Because they are able to attack a broad range of soils anionic surfactants are used frequently in soaps and detergents. This is a biodegradable mixture of foaming and wetting agents. An example would be like cooling a glass of water with a single ice cube.

This simply means that air has been added to the foam solution to expand it 8 times the original volume.

How To Use Firefighting Foam On Fire Bio Ex

Stability Of Foam An Overview Sciencedirect Topics

How To Use Firefighting Foam On Fire Bio Ex

Choosing A Foam System Requires Examining Hazards Firehouse

How Does A Fire Fighting Foam Concentrate Work On Fire Bioex

3 Firefighting Foams Pfas Per And Polyfluoroalkyl Substances

How Does A Fire Fighting Foam Concentrate Work On Fire Bioex

3 Firefighting Foams Pfas Per And Polyfluoroalkyl Substances

Surface Active Agents Surfactants Types And Applications

3 Firefighting Foams Pfas Per And Polyfluoroalkyl Substances

Phos Chek Wd881 Class A Foam Fire Product Search

How Does A Fire Fighting Foam Concentrate Work On Fire Bioex

How Does A Fire Fighting Foam Concentrate Work On Fire Bioex

How Does A Fire Fighting Foam Concentrate Work On Fire Bioex

Types Of Firefighting Foam Vanguard Fire And Security

Despite Advantages Of Using Class A Foam To Battle Wildfires Use Is Down That Needs To Change International Fire Fighter

How Does A Fire Fighting Foam Concentrate Work On Fire Bioex